Various employed technologies FDM (Fused Deposition Modeling), SLS (Selective Laser Sintering), DMLS (Direct Metal Sintering Laser) and the dimensions of print-area until 900 millimeters allows Famax Tech to satisfy the various requirements of the customers, from the prototyping to the small productions and realization of parts for equipments.

Various employed technologies FDM (Fused Deposition Modeling), SLS (Selective Laser Sintering), DMLS (Direct Metal Sintering Laser) and the dimensions of print-area until 900 millimeters allows Famax Tech to satisfy the various requirements of the customers, from the prototyping to the small productions and realization of parts for equipments.

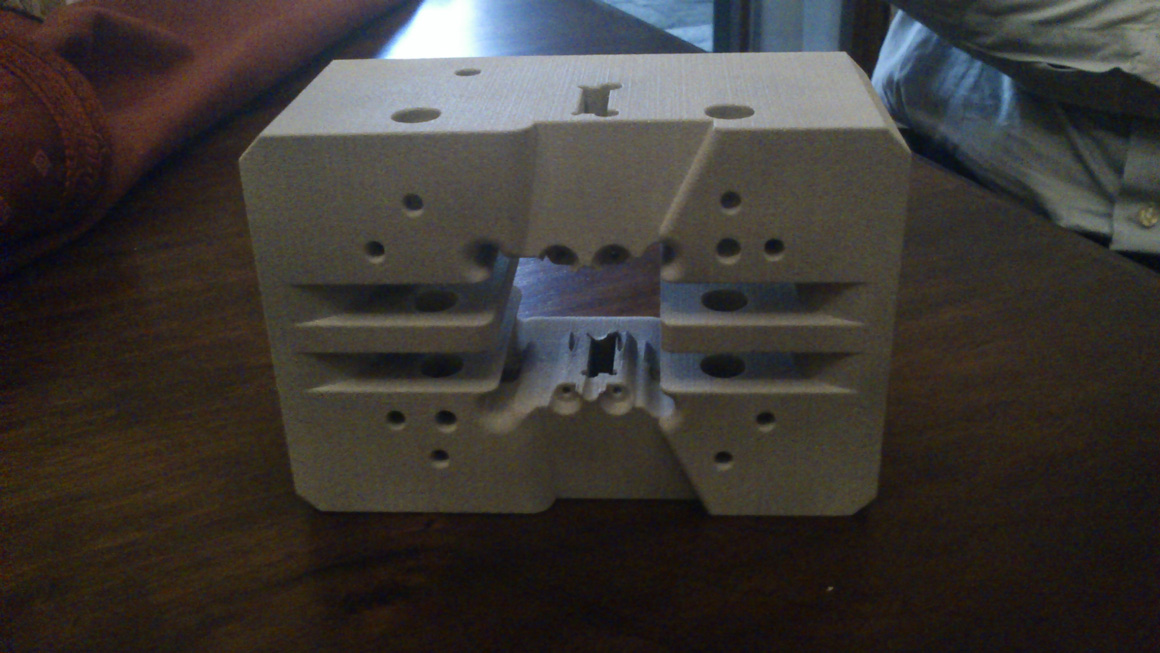

Technology that with a deposit to layers from fused plastic art allows the construction of tridimensional components eaven if they are empty and very complex.

The material used are tecno-plastic polymers that allows to produce components with very similar characteristics to those that will be subsequently produced on a large scale.

This technology gives the possibility to realize components which are perfectly working and extremely solid.

Similar to technology FDM it uses polymer powders with the addition of additives, fiber glass, aluminum, carbon etc. A laser beam polymerizes the layer of powder that becomes solid and tie in with that precedence. This technology is used in several sectors; naval, automotive and in the metallurgy industry.

Similar to technology FDM it uses polymer powders with the addition of additives, fiber glass, aluminum, carbon etc. A laser beam polymerizes the layer of powder that becomes solid and tie in with that precedence. This technology is used in several sectors; naval, automotive and in the metallurgy industry.

Similar to technology SLS, it uses metallic powders with elevated characteristic mechanics; aluminum, inox, titanium, chromium-cobalt, etc. Technology DMLS affords to realize metallic parts with density near 100% of the structure. To produce metallic complex parts is today possible.

Similar to technology SLS, it uses metallic powders with elevated characteristic mechanics; aluminum, inox, titanium, chromium-cobalt, etc. Technology DMLS affords to realize metallic parts with density near 100% of the structure. To produce metallic complex parts is today possible.

Aerospace, Automotive, Motorcycle, Naval, Military, Electrical appliances, Design, Medical, Dentistry, Prosthesis, Production, Equipment for industry, Educational , etc.